Contributor : Sudip Chakraborty and Ranjan Kumar

Significant improvement in battery technology and concerns over supplies of hydrocarbons are creating a marketplace for battery powered passenger vehicles in India. Electric Vehicles have been the transportation mode for at least 190 years but it has failed to get the customers’ attention. For the last few decades many researches have been conducted on vehicle dynamics, battery management systems, charging capacity etc. and now EVs are gaining market appeal. There are some technical factors which have a great impact on adoption, these are:

- EV Modelling.

- EV Battery Technologies.

- Recycling of EV Batteries.

- Charge Carrying Capacity.

This subcompact crossover SUV named TATA NEXON was marketed in 2017 but from 2014, the prototype was displayed in Delhi. TATA has recast the model into a Hybrid Electric vehicle which has been named as TATA NEXON EV and it was launched in December, 2019 in India. This EV comes with three variants namely XM, XZ+, XZ+LUX.

The electric motor which is being used in this EV can produce 94.7039 KW power and 245 N-m torque. The battery pack of 30.7 KW-h allows the vehicle to run up to 312 km at a go at full charged condition. It is estimated that for an urban road, weekly commute is 250 km on an average for a particular car. So, full charge can help you to ride for a week. The powertrain hardware consists of a permanent magnet motor and a single speed gear box with liquid cooled battery pack. The EV has got two modes of driving namely Drive and Sport. Drive mode is suitable for city driving whereas Sport mode is used for highway driving. It can achieve 0-100 km/h in just 9.9 secs in Sport mode.

It offers owners to charge the car using both 15A socket and a DC fast charger. The EV battery can get 0% to 80% charge in 60 minutes using the fast charger where in regular charging, it takes 8.5 hours to get charged up to 90%.

Technical Specifications:

Motor & Transmission –

| Electric Motor |

3 Phase Permanent magnet synchronous Placed at Front Axle |

| Fuel Type |

Electric |

| Max Motor Performance |

127 BHP / 245 N-m |

| Power Consumption/Mileage |

10.33 Km/kWh |

| Driving Range |

312 Km |

| Drive Train |

FWD |

| Transmission |

Automatic |

| Emission Standard |

BS6 |

| Battery |

30.2 kWh, Lithium Ion Polymer, 320 Volt. (Placed under floor pan) |

| Battery Charging |

8.5 Hrs with AC Fast Charging |

| Others |

Regenerative Braking, Pure Electric Driving mode |

Suspension, Brake and Steering –

| Suspension Front |

Independent, Lower Wishbone, McPherson Strut with Coil Spring |

| Suspension Rear |

Semi-Independent; closed profile Twist beam with Coil Spring and shock absorber |

| Front Brake Type |

Disc |

| Rear Brake Type |

Drum |

| Minimum Turning Radius |

5.1 meters |

| Steering Type |

Power assisted (Electric) |

| Wheels |

Steel Rims |

| Spare Wheel |

Steel |

| Front Tyres |

195 / 60 R16 |

| Rear Tyres |

195 / 60 R16 |

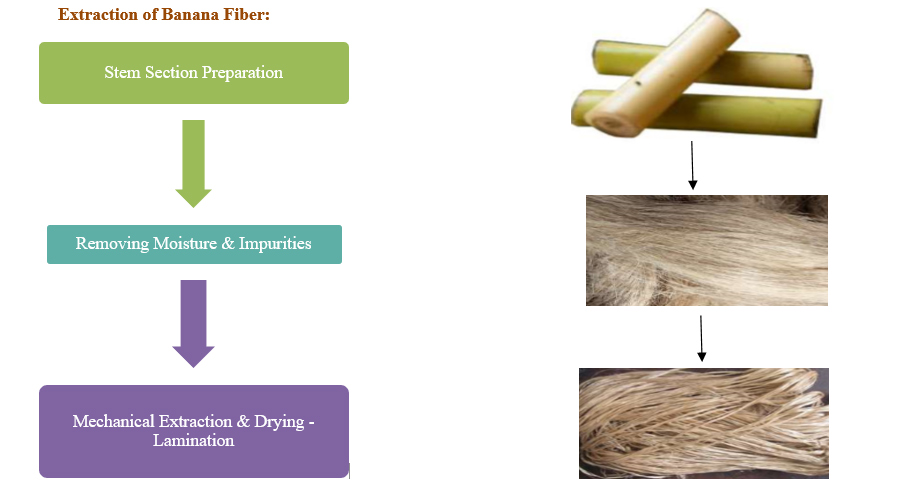

Modelling of NEXON EV. [Image Courtesy: www.autodevot.com]

Other Specifications:

- ABS (Anti-Lock Braking System) with EBD (Electronic Brake Force Distribution) for perfect car control during braking.

- Brake assist.

- Corner Stability Control.

- Reinforced body structure to protect during accidents.

- Dual airbags.

- Liquid-cooled IP67 battery pack to prevent overheating.

- Iso-fix anchorage.

- Hill Hold Control and Hill Descent Control for getting better grip on climbing hills.

NEXON EV: Exterior and Interior (Courtesy: autobics.com)

Technical comparison between TATA NEXON EV and TATA NEXON (Diesel and Petrol Variants):

|

Technical Specification

|

TATA NEXON EV

|

TATA NEXON (Diesel and Petrol Variants):

|

|

Engine Type

|

3 Phase Permanent Magnet Synchronous Motor

|

1.2 Turbocharged Revotron Engine

|

|

Battery Type

|

30.2 KWh advanced Li-ion Polymer with Liquid Cooled Battery Pack

|

NA

|

|

Charging Time

|

8.5 Hrs

|

NA

|

|

Power

|

127 BHP

|

108 BHP with 5000 rpm

|

|

Torque

|

245 Nm

|

170 Nm with 1750-4000 rpm

|

|

Displacement (CC)

|

NA

|

1199

|

|

Number of Gear

|

NA

|

6

|

|

No. of Cylinders

|

NA

|

3

|

Dimensional Comparison:

|

|

TATA NEXON EV

|

MG ZS EV

|

Hyundai Kona Electric

|

|

Length (mm)

|

3994

|

4314

|

4180

|

|

Width (mm)

|

1811

|

1809

|

1800

|

|

Height (mm)

|

1607

|

1644

|

1570

|

|

Wheelbase (mm)

|

2498

|

2579

|

2600

|

Security Features:

|

|

TATA NEXON EV

|

MG ZS EV

|

Hyundai Kona Electric

|

|

Airbags

|

2

|

6

|

6

|

|

ABS with EBD

|

Yes

|

Yes

|

Yes

|

|

Parking Aids

|

Rear parking sensors with rear view camera

|

Rear parking sensors with rear view camera

|

Rear parking sensors with rear view camera

|

|

Isofix

|

Yes

|

Yes

|

Yes

|

|

Electronic Stability Control

|

No

|

Yes

|

Yes

|

|

Tyre Pressure Monitor

|

No

|

Yes

|

Yes

|

In Indian market, there are very few EVs which can run up to 300 km at one go, TATA NEXON EV is one of them. The cost of this car is comparatively lower and it starts from 13.99 lacs. Tata NEXON EV with a certified range of 312 km and battery warranty of 8 years/ 160000 km. Tata NEXON EV looks stunning because it has the flat grille and various blue accents which attracts the people. With a ground clearance of 205mm, it stands tall and takes a good space on the road. As it is based on the Tata NEXON facelift, it looks fresh. The interiors look nice too with a central touchscreen, semi-digital instrument cluster and flat-bottom steering wheel adds to the sporty feel. Tata Motors joins hands with Tata Power to set up charging stations. Supporting the Indian Government’s ‘National electric mobility mission’, Tata Power established the first set of Electric Vehicle charging stations in Mumbai. Now present the charging stations are already set up in Mumbai, Delhi, and Hyderabad. Tata Power will set up more charging stations for a better adaptation of electric mobility.