Mechanical Engineering is one of the oldest engineering branches which produce graduates for leadership positions in core sectors like manufacturing, automobile, power plant etc. The studies associated with this branch are getting smarter day by day to be acceptable in every sector in engineering field. It has been come out form the orthodox shell and becoming essential for every technological innovation. Mechanical Engineering is a study combining physics and mathematics to design, analyze, manufacture and maintain mechanical systems. Here are some basic interconnections of this study with other engineering disciples.

Structures are made by the civil engineers may experience vibration, thermal stress and other stresses due to abrupt loading, naturally or synthetically. Those need to be monitored periodically using mechanical engineering studies. The famous Eiffel tower produces its own electrical energy using a wind turbine which can produce 7 GW energy per year roughly. Vibration causes for installing the turbine on the structure, 130 meters above the ground, a mechanical consulting company Getzner is looking after this, they have installed bearings for the turbine to minimize the frequency of the vibration and restrict it to reach to its resonance. Vibration simulation can be done using the knowledge of Computational Fluid Dynamics in ANSYS Workbench software using multi-physics. For any kind of large structures, two important phenomenons are there to be monitored. Temperature which expands the metals in a structure causes thermal stress generation and another one is wind, which provides large horizontal forces to the structure leads to bending as a structure is fixed at the base. Measurement methods for monitoring those natural impacts which can’t be controlled will be provided from the mechanical engineers using high end metrological devices and CFD study

A wind turbine is being installed on Eiffel Tower, Paris [Source: www.popularmechanics.com]

Rankin cycle is used in mechanical engineering study in a power plant to generate electricity from hydraulic energy. This is to be noted that we cannot get electrical energy directly from a power plant be it thermal or hydraulic. First, mechanical energy is to be produced using turbines and then using a generator or dynamo electrical energy can be produced for using through distribution. This is very clear that to produce electricity, knowledge of basic thermodynamics is required, so in UG study of Electrical Engineering, one paper based on Applied Thermal Engineering must be there for the aspiring electrical engineers. Structures and other parts of motor, generator and other electrical devices like rotor, stator, windings, rings and brushes are made of cast iron, mild steel, magnesium, copper etc. The one, who deals with the working principles of those electrical devices, must know the effect of those materials on their working. Now a days, smart materials are being used energy harvesters. These mechanical studies are important in electrical engineering field as well.

Rotor part is being manufactured

3 Phase Induction Moto with winding (Used Material: Copper and Mild Steel)

As Mechanical Engineering studies has adopted additive manufacturing, it has become popular in electronics engineering field as PCB boards are being designed and manufactured using 3D printed technology. Autodesk has provided another simulation tool named Fusion 360 where additive and generative manufacturing systems can be designed and simulated. Various sensors are being used and calibrated for measuring temperatures, pressures and other parameter for fluid flow, boilers, mines and other systems. A clear understanding of mechanical engineering studies are required to develop logic of those sensors using arduino.

PCB is being manufactured using 3D Printed Technology (Additive Manufacturing) [Source: www.robohub.com]

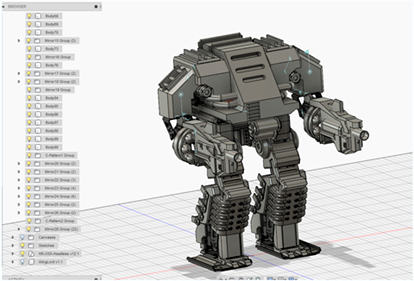

In Robotics, the arms and other hardware are manufactured using modern edge manufacturing processes using different materials depending upon the rigidity and weight of the robot. A robot is consist of links, joints and end effectors those can be designed and analyzed on the basis of degree of freedom which requires the basic knowledge of Kinematics and Dynamics in Fusion 360, CATIA, Solid works, NX by Siemens etc which are the pure design software based on mechanical engineering knowledge.

A robot is being designed in Autodesk’s Fusion 360 [Source: www.twitter.com]

Manufacturing sectors are adopting AI, ML for creating efficient operating model for their business. The computer science engineers who are current dealing with Artificial intelligence, Machine learning and data science in manufacturing sectors must have clear idea about machining time, failure theories, tool life, plant layout, operation research etc.

Bio-Medical studies also have two major subjects named bio-fluids and orthopedics. Both the areas demand the knowledge of fluid mechanics and mechanism of links and joints. Even the study of blood circulation through heart can be explained better using pump theory and conservation of mass theory.

The smarter mechanical engineering studies have been accepted and merged to other allied engineering studies as well. Those are Acoustical Engineering, Aerospace Engineering, Automotive Engineering, Marine Engineering, Railway Engineering etc.

Mechanical Engineers need to tighten their BOLTS and continue contributing to every sector for a better and safer world.

“A vibration is a motion that cannot make up its mind which way it wants to go.”

Visited 1801 times, 3 Visits today