It’s been just more than10 years, on 2009 UN announced that this year is the year of Natural Fiber because a million of people got employment in Europe in Natural Fiber industries. From that year, many researchers and scientists of Asian Countries like Japan, India, and Philippines etc devoted their skills to develop fibers from natural resources. Consequently, with the continuous research, Natural Fiber has become so popular in Engineering Materials sector; now, it is being used to make aircrafts, structures, containers, vehicle parts etc. The main USP of natural fiber is its weight, its way lighter compared to the other materials having same volume and it does not comprise to stress and stiffness which has made it to be accepted by the engineers dealing with larger structure with lesser weight. This very reason makes it a boon in aerospace industry.

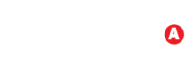

Banana stem which is considered as a complete waste is used as a source. From this, one of the strongest fibers of the World is developed. Banana fiber aka Musa Fiber is used to make tea bags, sanitary napkins, Japanese Yen notes and car tyres etc around the globe. Banana was domesticated around 8000 BCE in the Kuk valley of New Guinea. Evidences are there that banana fiber was used in 13th century for making ropes in South East Asia and the South Pacific, Nepal and Japan. Now, the commercial value of the fiber is being increased over the years.

It has given an immense area to the researcher for carrying out the research works on composite materials as synthetic can be substituted by the banana fiber from in composite wall production.

Why Banana Fiber is so popular???

- Soft, Supple and Shimmer

- Bio degradable

- Natural Sorbent : Fabric from theses fibers lets you breathe well and will keep you cool on hot days.

- Resistance

- Durability

- Insulation

- Tensile Strength

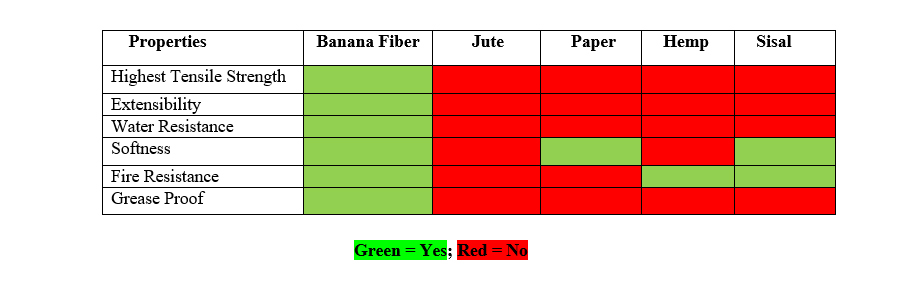

Physical and mechanical properties of banana fiber were examined and it is being used in the industries according to the properties. The fiber has got higher aspect ratio compared to other fibers and exhibits better tensile strength.

If we talk about the future of the Banana Fiber, is very promising as it is lighter, superior in properties and composition and cheaper compared to the other natural fibers. Here is the comparison with other natural fibers like jute, paper, hemp and sisal.

These properties have made this fiber useful for using in various fields of engineering like in high performance applications such as sports materials, aircraft industries and shipping industries etc.

The Department of Chemical Engineering, Concentration Textile Engineering, Universitas Islam Indonesia (UII) has been doing research on durability of banana fibers, it has been investigated that the durability can stay up to 3 months of storage, if the period is extended, the durability decreases significantly. Thermogravimetric analysis (TGA) is done on the fiber to analyze the heat stability or thermal degradation. The figure describes the TGA analysis and it is shown that it can work under a handsome range of temperature and it is used as insulator as the thermal conductivity of the fiber is 0.0253 W/m2K.

Commercial value in 2020!!!

A significant number of Banana Fiber extraction plants are running successfully in various parts of South India., some plants are exporting products as well. Apart from the uses in heavy industries, the banana fiber has become very popular in boutique sectors also. Banana fiber is used for weaving attractive pieces of clothes, rugs, sarees etc. Besides, it is also being used to produce a variety of items such as hats, photo frames, trinket boxes, gift bags, picture frames, hand bags, belts, baskets and sandals etc. Dresses woven out of natural fibers are in great demand inside and outside India. Even in India, it is said that the total cost for opening a plant is only 1.6 lacs where the return on invest is 98 % in this business. According to the market researchers the annual production of Banana Fiber has become 100,000 tones around the globe in 2019. Here is a representation of production across the world in 2019. It shows the potential of India in adopting the natural gold as business.

“Why join the Navy if you can be a pirate?” – Steve Jobs

Visited 2420 times, 2 Visits today