Yes, it is possible! Greywater is non-industrial wastewater generated from household works like dishwashing, laundry and bathing. Before decay, it was just an imagination of treating wastewater and reusing it, but in today’s scenario, this is happening for treatment of greywater for non-potable or potable purposes. According to the researchers, it is anticipated that one out of every three people would encounter water scarcity by the year 2030 or by the same period, there will be around 2.7 billion people on the planet. Governments and citizens have become more conscious of the issue in recent years. Authorities’ in-charge of water management handles the issue of water security and poses several concerns. Reduced cost measures increased awareness of water usage, as well as the installation of water-saving devices. Rain water collection and greywater treatment systems are viewed as possible alternatives, particularly in developing nations, where water constraint is more prevalent.

Grey water treatment is adopted in India at many colleges, schools, and residential buildings. So, let’s have a look over “New trends for grey water treatment and their reuse using MBR technology – a case study”.

Keywords: Grey water, MBR, Bio reactor, Optical density, Ceramic membrane, etc.

Treatment of wastewater from Adamas University’s main canteen:

The main canteen (fig.1) is open throughout the week so, works like dishwashing, floor cleaning, etc. are done at regular interval of time from this activities consumption of freshwater is increasing whereas if this discharged water can be treated and send back to the canteen for such non-potable purposes, then it would be a sustainable step towards reducing the freshwater consumption along with it. Grey water has many effects on our environment as these are directly discharged into the environment has both long-term and short-term environmental and human health consequences. Pollution of the soil and groundwater as well as crop damage is caused by high boron, sodium, or surfactant concentrations. Greywater has nutrients which may also cause

Fig.1 Main Canteen of Adamas University canteen

problems. Furthermore, environmental accumulation of heavy metals and micro pollutants may cause toxicity through the food chain, causing ecological imbalance and having a deleterious impact on humans [1].

Moving towards the methodology:

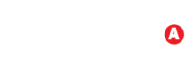

First of all, the work was started with a brief survey on work done and water consumed by the canteen, almost 12200 litres of water is discharged every day. This water was collected at the peak time (12 pm- 2 pm), and all the physicochemical parameters were checked which is shown below.

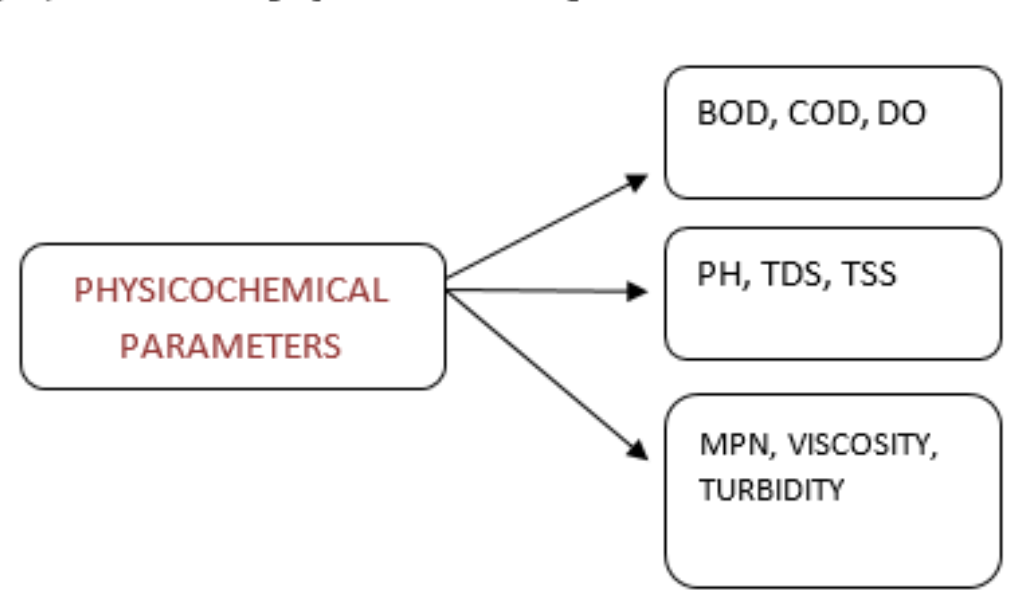

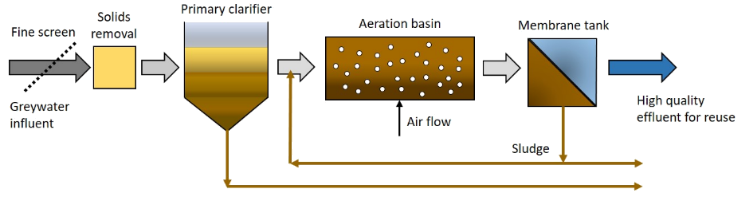

After a details study done on physicochemical parameters, the second step is biological treatment as the wastewater treatment is done with MBR (Membrane Bio-Reactor) and this biological treatment process is much more important in the full methodology. This method is much different and unique from another method as it’s a combination of both biological treatment and membrane filtration.

Fig 2 Principle of MBR

The membrane bioreactor consists of two primary parts as shown below where for biodegradation of waste compounds viz. biological unit is responsible and for physical separation of treated water from the mixed liquor membrane module is required. Various options are introduced for greywater treatment like simple treatment (coarse filtration and disinfection), chemical system (photocatalysis, electro-coagulation, coagulation, etc,), Biological system (biological aerated filter, rotating biological contractor, and membrane bioreactors), and natural system (construction of wet lands).

Working on bioreactor:

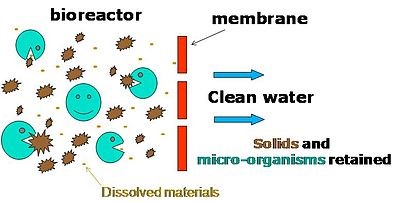

In this stage, a certain amount of grey water sample was mixed with activated sludge that was collected from STP (Sewage Treatment Plant, New Town, Kolkata). From this bacterial growth, the Optical Density (OD) vs. Time curve (fig.3) was also estimated which is necessary to determine the working efficiency of microorganisms present in the sample.

Fig. 3 Optical Density

In this step, three sets were done with different concentrations of sludge, and with regular time intervals. Optical Density (OD) was checked to see the growth of microbes using a double beam spectrophotometer with 600 wavelengths [2].

Types of MBR setup:

Figure 4 shows two types of MBR set up in which one is side stream (fig.4(a) and the other one is submerge MBR (fig.4(b)). Here we have used the side stream MBR set up for the experiment.

What is Membrane technology?

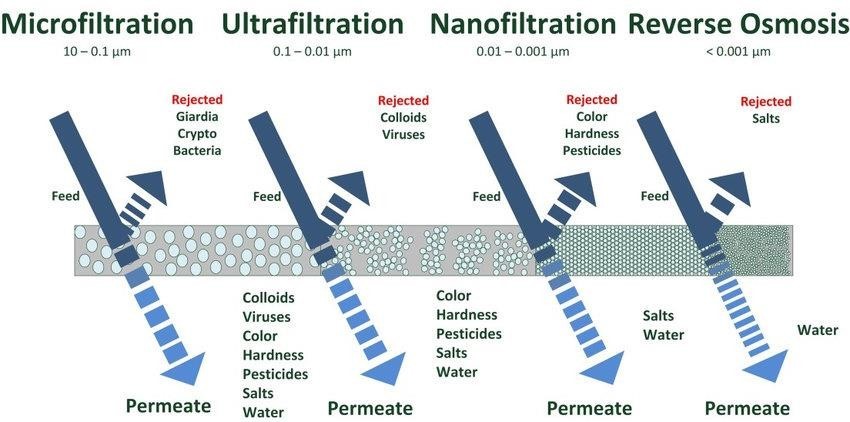

Membrane technology has been adopted by all the engineering approaches into day’s scenario. In the field of wastewater treatment membrane technology is getting important because with the help of ultra/microfiltration possibilities for removal of particles, colloids and macromolecules are more. So, this is more efficient and sustainable for the treatment of wastewater. A membrane can be defined as a thin layer of semi-permeable material which is used in solute separation as transmembrane pressure is applied across the membrane.

In the present work, ceramic membrane is used, ceramic membrane consists of solid layers of metal oxide (e.g., palladium, silver,zirconia, alumina, titania, etc.), It has a lifecycle of up to 20 years which may be used in potable water treatment, food and dairy industry, chemical industry, etc. Flat sheet, hollow fibre, multichannel tubular element, and monolithic are some of the forms in which ceramic membranes are available [3].

Classification of pressure-driven membranes and schematic illustrations of their operation is according to the pore size as shown in figure 5.

Fig. 5 Classification of pressure driven membranes and schematic illustrations of their operation are according to the pore size.

After completing all the procedures, the last step is filtration with a ceramic membrane to obtain the pure permeate water.

Fig. 6 Schematic diagram of Greywater treatment with ceramic membrane bioreactor technology [4].

As of now around 300 working in different parts of the world, Japan utilizes mostly this technology which are being used for water reusing in their locality. In India, MBR technology is now being used as CSIR-CG&CRI, Kolkata has developed their indigenous ceramic membrane technology.

After reading the above content, the question may arise in the reader’s mind why membrane technology? Why not the conventional technology or any other? What advantages we are getting from this. So, the advantages of using ceramic membrane are as follows.

MBR is an alluring and plausible innovation for on-site treatment applications. Predictable supplement expulsion is conceivable with the MBR technology. MBR is more effective in treating wastewaters that are challenging for conventional biological treatment systems. In India MBR technology is adopted by many industries now a day.

|

|

MBR Technology |

Other technology |

|

MLSS membrane fouling |

low |

High |

|

Membrane flux |

Low |

High |

|

Recirculation energy |

Low |

High |

|

Scanning requirement |

Low |

High |

|

Footprint |

Low |

High |

|

Effluent quality |

High |

Low |

|

Energy required |

Moderate |

High |

It was seen that the MBR technology with ceramic membrane works efficiently with comparison to other technology. This can be adopted in our university to return the treated water in the canteen for non-potable purposes. A step towards sustainable development!!

References

- Majumdar, S., Sarkar, S., Ghosh, S., Bhattacharya, P., Bandyopadhyay, S., Saha, A., … & Roy, S. N. (2018). New Trends for Wastewater Treatment and Their Reuse Using Ceramic Membrane Technology: A Case Study. In: Singh V. P., Yadav S., Yadava R. (eds) Water Quality Management, Water Science and Technology Library, 79, page 339-348, DOI: 10.1007/978-981-10-5795-3_29,Springer, Singapore (Online ISBN:978-981-10-5795-3).

- Racar, M., Dolar, D., Karadakić, K., Čavarović, N., Glumac, N., Ašperger, D., &Košutić, K. (2020). Challenges of municipal wastewater reclamation for irrigation by MBR and NF/RO: Physico-chemical and microbiological parameters and emerging contaminants. Science of the Total Environment, 722, 137959.

- Bandyopadhyay S, Kundu D, Roy S N, Ghosh B P, Maiti H S (2006) Process for preparing water having an arsenic level of less than 10 PPB. US Patent 7014771.

- Bhattacharya P, Ghosh S, Sarkar S, Majumdar S, Bandyopadhyaya S (2011) Effectiveness of biosorption assisted microfiltration process for treatment of domestic wastewater. Bioremediation J., 15:206–217.

Visited 1007 times, 1 Visit today