Optical fiber is a filament of transparent dielectric material like glass or plastic usually cylindrical in shape which is a guidance system for light. Guidance of light is achieved through multiple total internal reflections (TIR) at the fiber walls. There are some optical fibers which have been designed for the special purpose called ‘special fiber’ having non-cylindrical core and cladding layer, generally, an elliptical or rectangular cross-section. ‘Crystals’ always represents periodic structures in space. In the electronics industry, crystal structure control and manipulate electrons as it creates energy gaps by allowing only electrons with certain energies to propagate with preventing the propagation of other energies.

Can analogous energy gaps be designed for the light propagation in a medium?

Photonic crystal: Science or nature

We can control light or ‘photon’ propagation in a periodic medium by any materials that create energy gaps for light propagation and it is referred to as a ‘photonic crystal’.

Photonic crystal structure is possible in fiber when it is made with a regular pattern of index variation. Light is confined within such fiber by diffraction effects instead of or in addition to total internal reflection, to the fiber’s core. The properties of the fiber can be customized to a wide variety of applications.

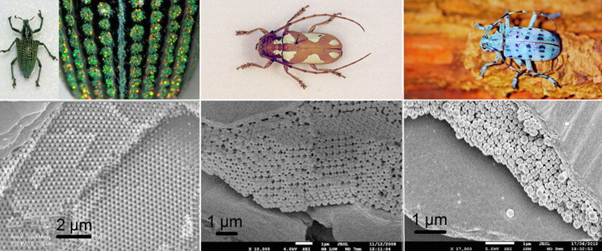

Photonic crystals are not innovative to our nature. They have been observed in the bright coloured coats of insects such as longhorns. Various species are able to show different colours by varying the periodicity of the crystals. Peacock feather, Morpho butterfly, sea mouse hair, natural opals etc. are brilliant existence of natural photonic crystal. Modification of chameleon skin colour is possible by changing the periodicity of the photonic crystals on its skin.

Picture courtsey: Science Direct (Longhorn species, different colours by varying the periodicity of the crystals)

Introducing pathway by Philip Russell

In 1996, Philip Russell first demonstrated PCF structure. He proposed that the designing and fabrication method of PCF depends on the number of dimensions that the photonic band gap must exist such as one dimensional, 2-dimensional and three-dimensional. The photonic crystal structures due to periodic variation of dielectric along the different (one, two and three) direction.

- Index-guiding PCFs

The index-guiding PCF has solid core same as conventional optical fiber. It is made by packing a series of hollow glass capillary tubes around a solid glass core that runs through the center. This fiber guides light by TIR, because the cladding with its air holes effectively has a lower refractive index than the core.

- Photonic band gap fiber

In photonic band gap fiber, the core is a region with an extra hole, which is low-index defect. The cladding, therefore, has a higher refractive index than the core and so guidance by conventional TIR is not possible. In this case, the light is actually guided along the low-refractive-index air core by a photonic band-gap confinement effect.

Picture courtsey: Laser focus world (Figure a, b & c, PCF manufacture by Stack and draw technique),Google image (Figure d ,PCF spool, commercially available in market),Google image (Figure e cross sectional view of hollow-core PCF), http://dx.doi.org/10.1103/PhysRevLett.109.024502 (Figure f, Light guided in hollow-core PCF)

Manufacture and Commercial availability of PCF, which change different global technology

Most of the PCF manufacturer use stack-and-draw technique to design PCF, which basically consist with following steps: firstly, constructs a “preform” on the scale of centimetres in size, then heats the preform and draws it down to a much smaller like a human hair diameter, maintaining the same features of preform. Over 50 companies offer PCF all around world with different specifications like Thorlabs, NKT Photonics, Newport, YSL Photonics, Fiberware, GLOPhotonics SAS, ELUXI Ltd. etc. In India, CGCRI-Kolkata is front line PCF manufacturer.

Benefit of PCF, why technology demand it?

Ascending from a technology stalwartly attentive on telecommunications, recently optical fiber is expanding in some diverse fields as biotechnology, astronomy and medicine. One particularly attractive feature of PCF structures is highly uniformity over long distances. This means that when light launched in at one end of fiber has time to sort itself out into a single mode. It permits highly reproducible detectability. Essentially, undesirable cladding modes are efficiently filtered out before they can interfere with any measurement which increase quality of any measurement.

In 2000, most celebrated application of PCF is supercontinuum generation from un-amplified Ti:sapphire femtosecond laser pulses at 800 nanometer wavelength. Thereafter, hollow core PCF(HCPCF) has been utilized in many captivating applications, such as gas-Raman cells for high efficiency, low threshold color-conversion of laser light. In 2002, HCFCF was used in laser-tweezer propulsion and guidance of small particles along a curved path. Recently, demand of HCPCF increase in area of optical sensing, with myriad opportunities crossing many fields which includes environmental detection, biomedical sensing, and structural monitoring.

Contemporary Laser and Sensing technology

Commercially available white light supercontinuum sources are speedily becoming an essential tool in laboratories worldwide and in commercial microscopes. High power industrial PCF based laser research, manufacture and use are overwhelming day by day. The advantages of PCF based laser are low operating costs, high beam quality and high efficiency in a maintenance-free format with a small footprint and low weight.

Many bio-hazardous gases, includes methane and hydrogen halides have their absorption in the near infrared region. In gas sensing process, gas is allowed to enter into the surrounding holes in the PCF as it will absorb the evanescent light from the core fiber. Depending on the intensity of the absorption wavelength, the output power is reduced strongly at the wavelength of interest. Similar mechanism is also followed for sensing fluids and biomolecules. Likewise, PCF laser, PCF based sensor research are encouraging sensor market as within a few years it could share at a significant way and are projected to be the industry standard.

If anybody is interested to utilize photonics as sensing technology, then future industry will bring a huge market for the accessory instruments with a numerous of other advantage. There will be increasing demand for more effective cleavers, low-loss splicers, multi-port couplers, intra-fiber devices, and mode-area transformers etc. Government of any country should invest on PCF based laser or sensor project. R & D sector needs to think more. Consequently, through photonic crystal fiber based technology, we are approaching superior technology, huge job opportunity and an improved world.

Visited 1912 times, 1 Visit today