Dr. T. Senthil Vadivel & K. Narasinga Rao

Professor & Head / Civil Engineering, School of Engineering & Technology, Adamas University, Kolkata – 700126.

General Manager – Head Engineering, Volta Green Structures, Hyderabad – 500 084.

Preamble:

It is expected that in India lockdown going to be extend up to 1st Week of May 2020 to flatten the curve but anyway some limited relaxation will be given in the urban centres and rural areas to help the poor and supporting former to harvest Rabi Crop. Since COVID-19 is a communicable disease, once relaxation started in practice then it is essential to be ready with enough healthcare facilities especially infrastructure with more quarantine facilities, isolation wards and testing laboratories as soon as possible. On a lighter note, this is the first time that the entire world inspired by a Civil Engineers’ medicine (i.e.) “Stay at Home”.

Solution: Modular Construction:

The modern construction industry provides an apt solution for planning temporary treatment centre by a novel construction technique known as Modular Construction. These structures can be built fast, can be modified as per the requirement and even be transported to places where the necessity pertains.

Modular Buildings:

Modular buildings are produced by pre-engineered building units in factory with different units and assembled in the site. The following steps involved in the construction of Modular Buildings.

- Unit Fabrication: Hot Rolled and Light Gauge Steel Frame (LGSF) Unit is used for this fabrication. Hot rolling is for shaping and LGSF is made up of galvanized iron steel by cold forming process. These sections are called as Studs and Tracks.

- Framing: Stud is the main framing component and Track is used as a closure. Based on these different framings like Walls, Floors, Doors and Windows are framed.

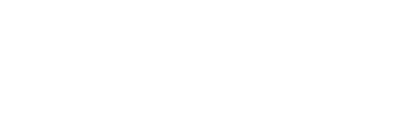

Fig. 1 Hot Rolled Steel Assembly

Fig. 2 Hot Rolled & LGSF Infill Assembly

- MEP Fixture: After framing essential Mechanical, Electrical and Plumbing Units are incorporated.

- Exterior & Interior: Fixing of Wall Panels, Floor Panels and Deck Sheets will be carried out based on the requirements. Since it going to be serves the needs of hospital, essential health care unit requirements need to be taken care of.

Fig. 3 Exterior View

Fig. 4 Interior View

- Transporting & Assembling: Once all ready the units can be taken to the site and assembled like a puzzle to produce a Modular Buildings.

Fig. 5 Transporting & Assembling

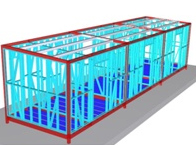

Fig. 6 3D View of Isolation Room

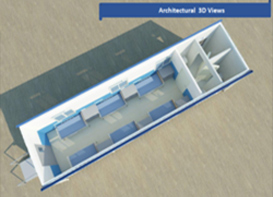

Fig. 7 3D View of Quarantine Ward

Why Modular Building?

- Low cost and can be constructed rapidly.

- Flexible construction and it is completely reusable.

- High strength and light in weight. Hence it is earthquake resistant.

- It provides more carpet area since the thickness of the wall is very less.

- It is suitable for all the places even in sloppy terrains.

Proposed Isolation Ward/ Quarantine Centre:

- Ward Size : 12 m x 3 m

- Height : 2.5 m

- Carpet Area : 350 square feet

- Unit Specification : Constructed with steel frame, light gauge steel walls covered with puff panel with suitable insulation for thermal control and flooring with high density wooden flooring.

- Time of Construction : 10 Days (one module)

- Transportation : By Trailer/ Truck (40 ft)

- Weight of Module : 4 MT

- Design : Indian and International Standards

- Recyclability : 80%

Visited 2484 times, 1 Visit today